TwinTeeth - Assembling the Solder Paste Dispenser

The solder paste dispenser Toolhead consists in a mechanism moved by a small stepper motor which actuates a luer-lock syringe. It allows dispensing small solder paste spots on the SMD PCB pads.

To build the Solder Paste Dispenser Toolhead you will need the following material:

| QTY | Name |

|---|---|

| 1 | Dispenser ToolHead Hexagon |

| 1 | Set of Dispenser Toolhead printed parts |

| 2 | 3mm steel rods - 134mm |

| 1 | M5 x 140mm threaded rod |

| 1 | M3 x 151mm threaded rod |

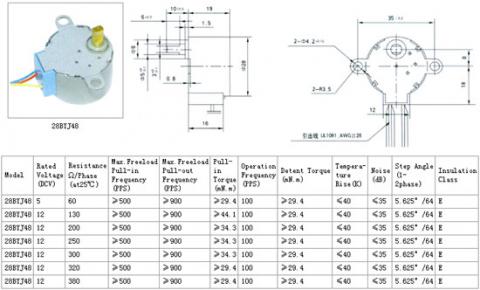

| 1 | 28BYJ-48-12V motor (hacked to convert it to bipolar) |

| 1 | 10CC Dispensing luer-lock srynge |

| 1 | Dispensing needle |

| 1 | 20mm of flex. plastic tube 5mm inside (motor coupler) |

| 1 | A4988 Motor Driver + Radiator (shared with 3D printer Toolhead) |

| 1 | Female DB15 Connector 2 rows + casing |

| 2 | M3 x 8mm allen screws |

| 2 | M3 x 10mm allen screws |

| 6 | M3 nut |

| 2 | M5 nut |

| 1 | M5 nyloc nut (optional top) |

| 2 | Drops of oil |

Preparing the 3D parts

Review all the plastic parts before assembling them and remove with a cutter the remains of support material, plastic chaffs, blobs, strands, threads, etc. that could be left from the 3D printing process.

Using a 3mm drill bit go into the holes of the parts where the linear guides will be installed (3mm steel rods - 134mm).

Take special consideration with the Carriage (see next picture).

Insert on it the 3mm linear guides and check that they slide smoothly and without too much play.

Using a 5mm drill bit go also into the holes where the M5 x 140mm threaded rod (leadscrew) will be installed. It's the central hole of all the pieces. Check that the rod goes through them and it does not have contact with the hole walls.

Using the soldering iron, insert one M3 nut in the Motor Support part and two on the Syringe Holder Bottom part.

Insert a M5 nut in the Carriage trap. This is the nut which travels through the leadscrew so be careful to install it correctly. Use a little melted plastic to maintain it in its position.

Preparing the stepper motor

The dispenser mechanism uses a 28BYJ-48-12V motor. It's a small unipolar stepper motor which includes a 1/64 reduction gear built-in.

To use it in TwinTeeth, first we have to convert it to bipolar because the A4988 and the Ramps are designed for bipolar motors.

Modifying the 28BYJ-48 is very easy. All you need is a cutter and a tiny screwdriver.

First use the screwdriver to remove the blue plastic cap. It hides a small PCB which holds all the wiring connections.

Using the knife cut the central PCB trace where the red wire is connected. Cut also the red wire (see next picture).

Put the blue cover in its place. The motor now is bipolar and works with only two phases. One (2A, 2B) correspond to the wires pink and orange and the other (1A, 1B ) to the yellow and blue.

Now solder the wires to the DB15 female connector using the following pin configuration:

| DB15 | Description |

|---|---|

| 5 | Stepper motor coil 1-A - Yellow wire |

| 6 | Stepper motor coil 2-B - Orange wire |

| 7 | Stepper motor coil 1-B - Blue wire |

| 8 | Stepper motor coil 2-A - Pink wire |

Install the connector cover and tighten the screws.

Assembling the dispenser

Now we are going to assemble the dispensing mechanism.

First take the M3 threaded rod and insert it through the Motor Support hole till it will reach the M3 nut of the other side.

Then screw the rod into the M3 nut.

Insert the 3mm steel shafts into the Motor Support part holes (see next picture)

Slide through them the Syringe Holder Bottom part till it will rest on the Motor Support.

Then slide the Syringe Holder Top part till it will rest on the bottom part.

Install the Pillar part inserting the M3 threaded rod through it.

Bolt both Syringe Support parts with two M3x8mm bolts.

Now insert the Carriage through the 3mm steel rods.

Attach on the dispenser the Top Plate part and bolt it with a M3 nut.

Put a drop of oil on each steel guide and check that the Carriage slides smoothly through the guides without blocking.

Screw 10mm a nut through the M5 threaded rod. Trim to 20mm the plastic tube for the motor coupler and screw the M5 threaded rod into it till it will touch the nut (see next picture).

Insert the threaded rod through the hole of the Motor Support , then through the holes of the Syringe Support. Screw it on the M5 nut of the Carriage till it will finally reach the hole of the Top Plate. Optionally you can screw there a M5 nyloc nut.

Put a drop of oil into the M5 nut of the carriage (it is better to use mineral grease or vaseline if you have)

The dispenser mechanism is almost complete. It will look like in next picture:

Installing the motor

Now we are going to install the stepper motor.

Insert the motor shaft into the plastic motor coupler.

Then attach the motor to the plastic part using two M3x10mm bolts.

Now the dispenser is complete and will look like this:

Installing the syringe

The dispenser ToolHead uses a 10cc Luer-Lock syringe (included in the kit).

To install the syringe in the dispenser first you have to introduce the syringe barrel into the syringe support plastic part. Adjust the syringe plunger to the appropriate distance and Insert the plunger end into the carriage housing.

Then turn the syringe 90 degrees to your right till it will get locked into the support. To uninstall it, just turn it to the left and pull from it to get it out from the dispenser.

Check that the locked mechanism works well and adjust the plastic parts with a soldering iron if needed till it will work smoothly.

Tip: The carriage was designed to hold syringes of different sizes. Some syringe models will fit better than others and there could be a gap between the plunger end and the carriage housing.To avoid any possible mechanical play we recommend you to use a wedge or something similar. Insert it between the plunger top end and the carriage plunger housing.

Filling the syringe

Commercial solder paste comes in different syringe sizes and types so you probably need to transfer some amount of paste to the 10cc syringe which the dispenser uses. You can not do that removing the plunger and filling the syringe barrel because you will also introduce air into it. So the only way to do it is from the syringe tip using some kind of adapter. You can find them in the market. They are Luer-Lock adapters specially designed for this task. But an alternative and easy way to do it is using a piece of 6mm silicone tube and connect both syringes with it (see next picture).

With this trick you just have to press carefully on the solder paste syringe plunger and transfer the amount of paste you want to the dispenser syringe.

Installing the dispenser

Before installing the dispenser check the hexagon part and remove with a cutter the remains of support material, plastic chaffs, blobs, strands, threads, etc.

Using a 4mm drill bit go into the side holes of the hexagon (the holes of the M4 retainer bolts).

Fill the syringe with paste, install it in the dispenser and introduce its barrel through the central hole of the hexagon till the motor will reach the top surface of the hexagon (see next pictures).

Then you can install the needle.

Installing the A4988 driver

If you did not do it before now is the time to install the stepper driver on the Ramps board.

Check that the printer is disconnected, paste the small Alu. radiator on the A4988 IC and insert the driver on the E0 position.

This driver is shared by the 3D Extruder motor and the Paste Dispenser motor.

Warning: take care when installing the driver on the Ramps because if you install it incorrectly you will destroy it. You will also destroy it if you connect/disconnect the motors while the power is on.

If you look at the board with the yellow fuses on your left, then the correct position of the driver is with its tiny potentiometer pointing to your right.

Connect the wiring to the new driver. Check that the connector is in the right position as we showed in Chapter 4 – Wiring the electronics.

The ToolHead is ready for use.

Check that the printer is disconnected. Insert the hexagon on TwinTeeth, lock it with the retainer bolts and connect the DB15 cable.

Testing the dispenser

Now we are going to test the dispenser. First install on the platform a PCB board which we will use for testing purposes.

Connect your computer to the Arduino and run TwinTeethMC. Then turn on the power supply.

Now, select the COM port and connect to TwinTeeth.

Click on the Paste Dispenser tab and then home the platform.

Setting the Program Zero

Using the Z control, move carefully the platform till the needle tip will touch the PCB surface.

Remember: go over the emergency button with the mouse in order to quickly click there and stop the robot in case something goes wrong. If you overpass the limits you could break the needle or the syringe.

Once the platform is in that position, click on the Calibrate button.

Set the Z min slider to zero because using the Dispenser ToolHead we don't need to go beyond that point.

Click on the Set Program Zero button to set the current location as the program zero.

Click again on the Calibrate button to hide the calibration controls.

Then home the platform again.

Now, click on the "Go to Zero" button to check that the platform goes to that position. The platform will stop just when the dispenser needle touches the PCB.

Dispensing some paste

Now we are going to learn how to dispense manually some solder paste, just to see that the dispenser works well and feel how it works.

When you selected the Paste Dispenser tab on the TwinTeethMC menu, you could see a new set of controls:

They are the Paste Dispenser controls, similar to these:

On your right, you will see an arrow button pointing downwards. If you click there you will move the dispenser actuator the mm showed in the mm field. It will move at the speed showed in the mm/min field. Both fields are slider controls so you can go over them with the mouse and click and drag to left/right to change its value.

The arrow pointing upwards is the reverse control. It will move the dispenser actuator up in a similar way that the downward arrow moves it down. It is useful to stop dispensing. Paste dispensers usually have some hysteresis and the paste continues flowing after it stops moving. So the usual way to stop the dispensing is to reverse some mm the actuator.

The forward and reverse buttons are also useful to move the actuator to the position where it is possible to install the pre-filled syringe on the dispenser. Remember that you must load the syringe with paste from the tip so the plunger will move out of the barrel some centimeters depending of the amount of paste transferred. When you try to insert this pre-filled syringe into the dispenser you will see that you have to move the carriage manually to the appropriate position and insert the syringe plunger in it. This is because you can not move the plunger (if you do it you will introduce air into the syringe, and it is not good).

Now we will focus on the flow rate control. You will see that the speed has a narrow margin. This is because the motor has a 1/64 reduction built-in. This means that it can run really slowly. So slowly that you almost cannot see that it is moving. On the other side, if you increase the flow rate too much the motor will lose steps and slip, so maintain it in a reasonable value.

Now we are going to check if the dispenser works.

Click on the Home button.

Now select 1mm in the dispensing length slider and 196mm/min at the flow rate slider. Then click on the down arrow to dispense some paste. Then click on the reverse button to move it up.

If the motor did not move then something is wrong. First check if the A4988 driver is properly adjusted. Check that the potentiometer is at the right position as we showed in Chapter 6 – Calibrating the robot and adjust it if needed.

If it still doesn't move review the wiring and the DB15 connections. If continues not moving remove the motor from the dispenser and test it separately until you discover what happens.

The dispenser is ready. Before using it in a real PCB, take some time to familiarize yourself with it.

We will learn more things about how to use it in the "How to use it" chapter.

Previous chapter Assembly Index Home Next chapter